This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Our expertise

Adapting to the constantly changing customer needs.

What kind of products are you interested in?

Ultricies purus commodo arcu pellentesque sapien. Porta platea efficitur neque inceptos natoque quam curabitur. Suspendisse montes torquent luctus sagittis blandit nisl cubilia. Libero mattis nibh consequat class nunc.

Busbar manufacturing

Our busbar line is equipped with all the necessary tools to ensure impeccable automotive industry quality. In case of demand for powder-coated and galvanized busbars, we involve other companies within the corporate group in the production.

Waterjet Cutting

STM Premium 320 type CNC-controlled waterjet cutting machine, capable of handling components up to 50 mm thickness with ease. In addition to the 3700 bar pressure, we assist the cutting process by adding abrasive sand to achieve the highest quality. The cutting head can move at speeds of up to 40 m/min, positioning itself with an accuracy of 0.05 mm.

Laser cutting

Senfeng SF1313G, CNC-controlled laser sheet cutting equipment, capable of cutting up to 15mm thick steel sheets with excellent quality. With a working area of 1200 x 1200 mm, a power of 3 kW, and a positioning accuracy of 0.05 mm, it efficiently and reliably performs cutting for thinner products.

Grinding

CF type circular vibrator offers economical and highly efficient surface finishing technology. The equipment has a gross 200-liter working tank. With easy operation, low maintenance costs, and equipped with a pneumatic separation valve, the system can efficiently deburr multiple medium-sized products intensively. For smaller components, we use the centrifugal unit AVATEC-TE 6 HD to prevent deformation of the parts.

Milling

Alzmetall BAZ 15, 3-axis CNC vertical machining center with Heidenhain control. The main spindle, with a maximum speed of 9000 revolutions per minute, is capable of creating high-quality surfaces. The workspace load capacity is 500 kg, equipped with an SK40 standard tool turret. With a machining range of 600 mm x 400 mm x 600 mm, machining larger components poses no challenge.

Bending

Boschert Profi 28 CNC bending machine with hydraulic control. The back gauge in the Z direction and the bending angle are programmable. It has a pressing force of 280 kN, suitable for bending sheets up to 10 mm thickness. Bending length is 300 mm. Due to its extremely compact and robust design, the repetition accuracy of bends is 0.02 mm.

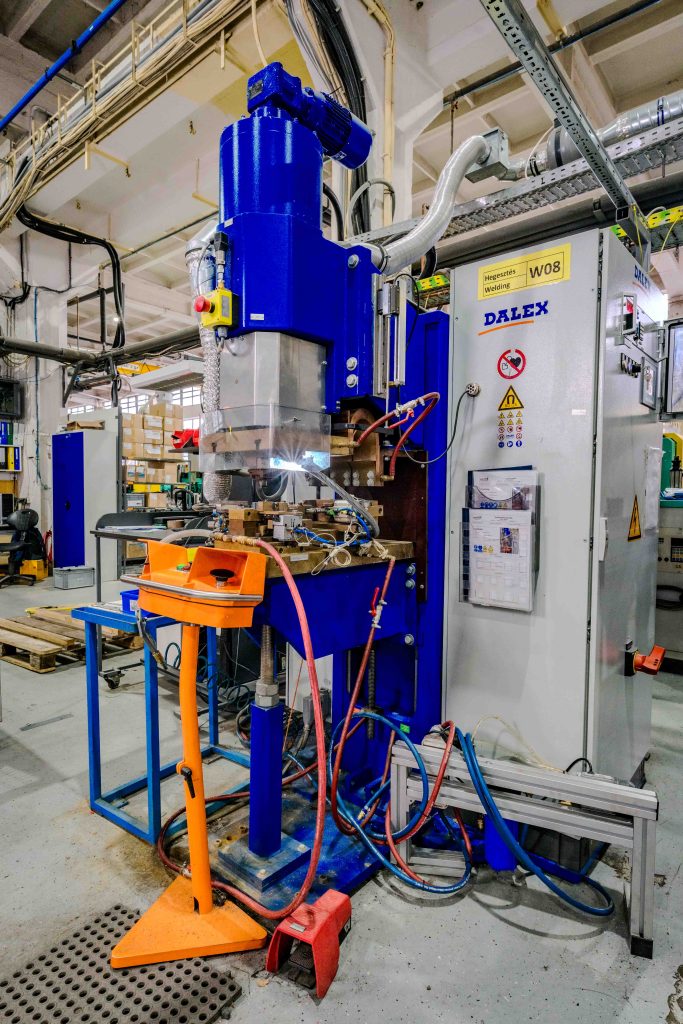

Welding

Dalex PMS 37-6MF resistance welding machine is excellently suited for prototype manufacturing, providing a rated power of 250 kVA and a modularly assembled working area. The current intensity, pressing force, and welding time are all adjustable, influencing a wide range of welds between the two carbon electrodes. Depending on the cooling technology, product cooling can be achieved using either air or liquid.

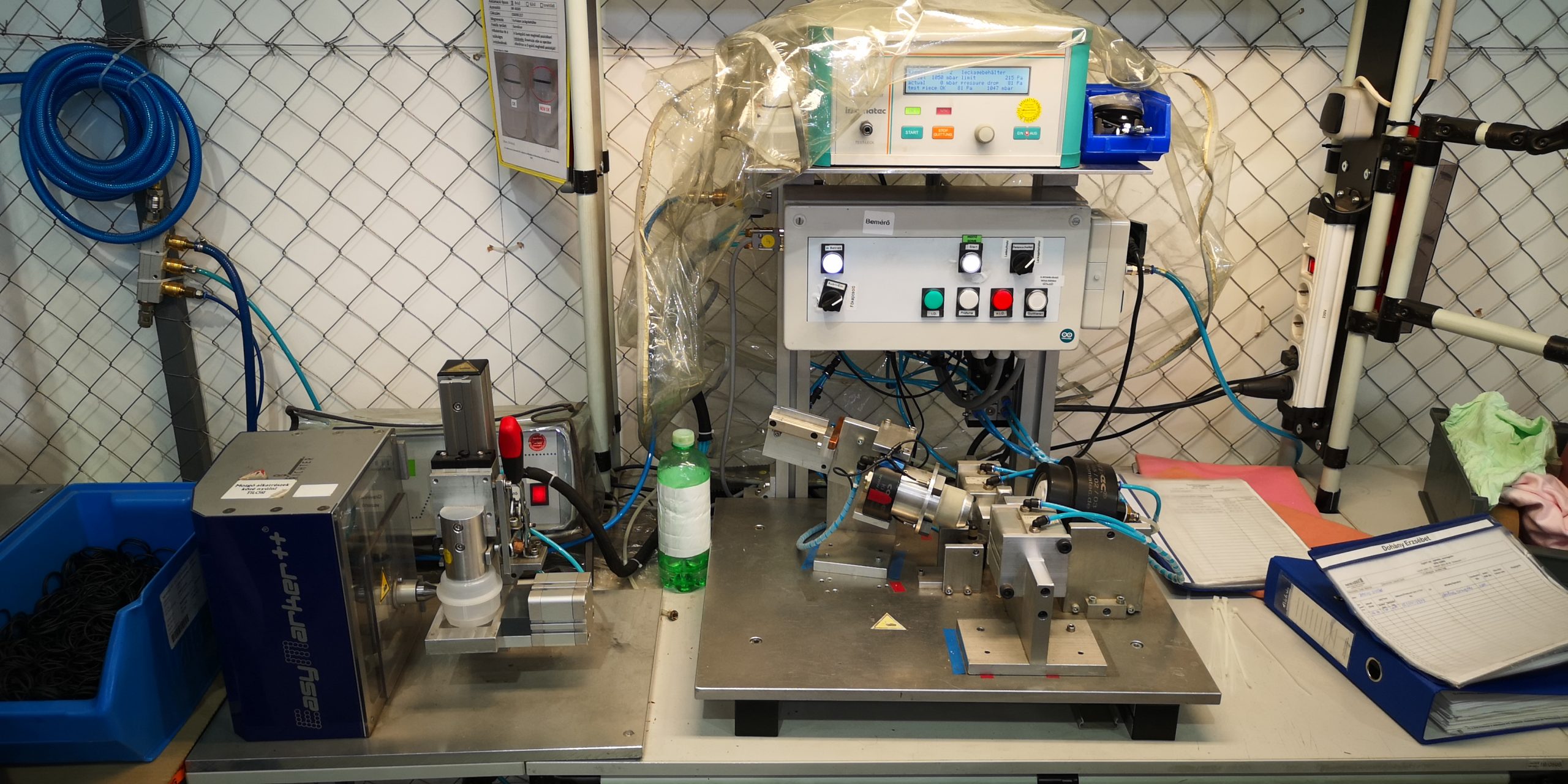

Laser marking

LG-60-J-01 – Laser engraving station. The heart of the machine is a JPT MOPA type laser with a power of 60 watts. It is capable of easily and quickly engraving metals and plastics. During the busbar manufacturing process, each finished product receives an identifier at the beginning of the process, which is engraved into the product using the machine in a data matrix format readable by a scanner. We track each phase in our own system.

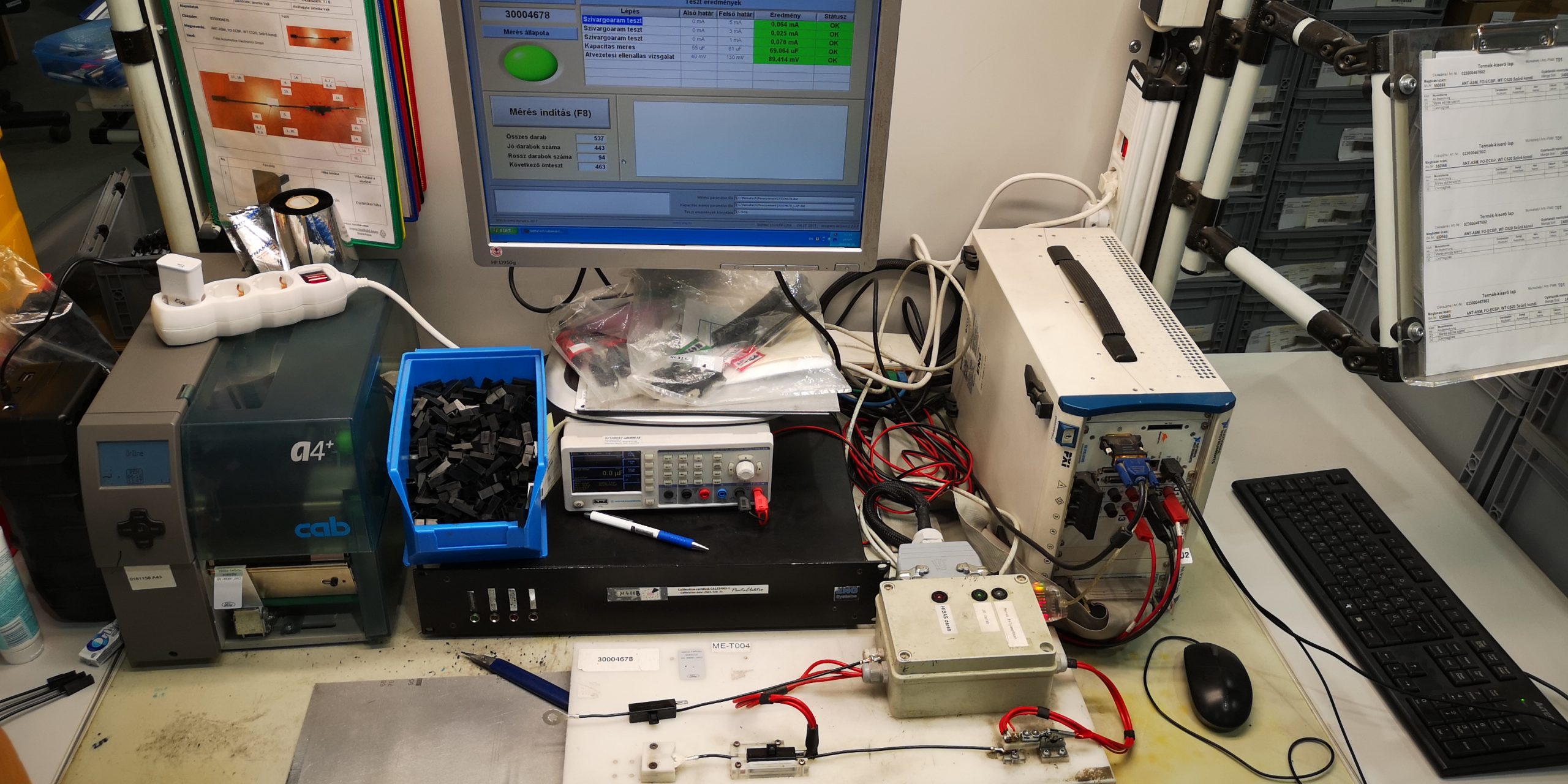

Measurement

Hexagon Absolute Measurement Arm 85 is a portable measuring arm with an advanced three-dimensional laser scanner. Through scanning, the point cloud of any (even amorphous) shaped product can be mapped. Subsequently, it can be compared with the 3D model of the product in PCDMIS metrology software, enabling the detection of any deviations between the actual and the designed product with an accuracy of 0.002 mm.

Hexagon Optiv Classic 321 GL coordinate measuring machine features a 6.5x CNC zoom optics with nearly 2 μm accuracy. In addition to optical imaging, it can be equipped with a probe for measuring products with precision narrow tolerance ranges. Using the PCDMIS software, a comparison is also made between the 3D model and the actual product.

Plastic components

Thanks to our diverse injection molding machine park, the range of producible components is very broad.

Cable harnesses, sensors, and other assembled products

Our assembly line is equipped with all kinds of machinery and tools necessary for efficient cable processing and machining.